What Does Motorcycle Parts New Zealand Specialists Do?

Table of ContentsHow Motorcycle Parts New Zealand Specialists can Save You Time, Stress, and Money.Motorcycle Parts New Zealand Specialists Things To Know Before You BuyGet This Report about Motorcycle Parts New Zealand Specialists5 Simple Techniques For Motorcycle Parts New Zealand SpecialistsThe Basic Principles Of Motorcycle Parts New Zealand Specialists An Unbiased View of Motorcycle Parts New Zealand SpecialistsAbout Motorcycle Parts New Zealand SpecialistsMotorcycle Parts New Zealand Specialists for Beginners

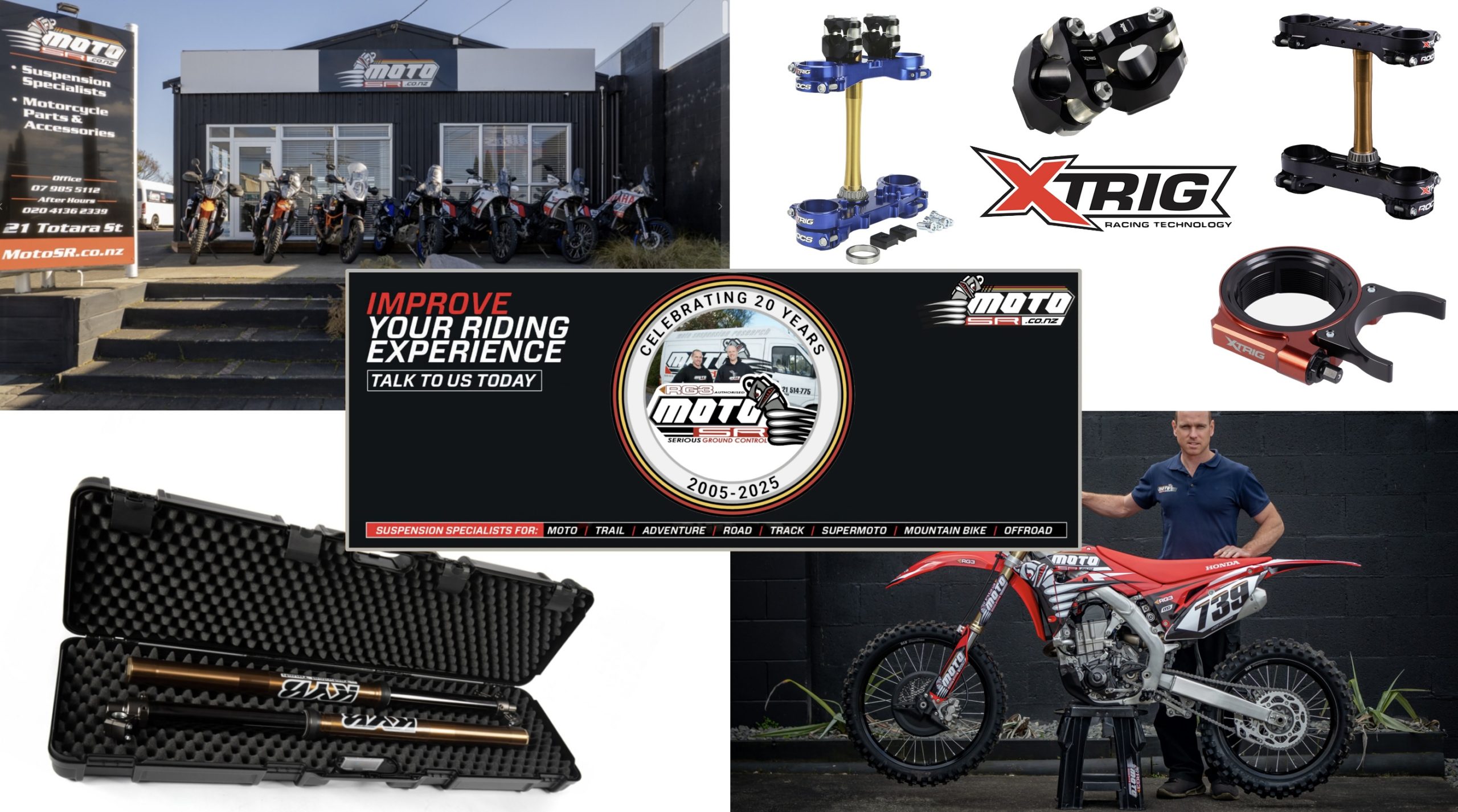

So, connect to among our specialists today.CNC machining innovation is rapidly coming to be the focal point of many various manufacturing processes around the world as a direct outcome of its numerous advantages over other approaches. Additionally, the sectors that produce bikes have hopped on board with this pattern. One of the most ingenious firms are now developing their engine components and wheels making use of machining techniques originally created for motorbike components.

You may be questioning why we make use of. Now that we have your focus allow us discuss the reasoning behind this modern-day growth in the motorcycle manufacturing market.

The Motorcycle Parts New Zealand Specialists Ideas

Additionally, you have total control over the appearance of the parts, also down to the min details. Occasionally, motorcyclists might make a decision to beautify their adventure by installing aftermarket parts or changing the bike's transformation. Once once more, computer system numerical control (CNC) machining is one of the most practical approach. Upgrades may be of any type and style you want.

The 6-Second Trick For Motorcycle Parts New Zealand Specialists

CNC machining might be made use of to make almost all of a motorcycle's metal and plastic components. To continue, we'll review several machined components for bikes.

Milling treatments are used to acquire the desired degree of wheel personalization. An additional facet of the motorbike that might be customized is the tires.

Motorcycle Parts New Zealand Specialists Fundamentals Explained

When it involves an automobile (or a motorbike), the most vital element is the engine. Numerous individuals mention it as the "heart" of the car. On the various other hand, the camshaft, the cylinder head, and the pistons often tend to be elaborate and call for styles with a high level of precision.

Use only high-grade products, however, since these lights are vital for the safety and security of motorcyclists and various other drivers or individuals on the road, particularly at night. Motorcycle fronts lights have 3 major parts: the light bulb, or light resource, the lens, and the real estate.

Milling processes with a remarkable finish would certainly result in the lenses having a reflective quality that resembles that of a mirror. The cover, on the other hand, is not composed of delicate materials; rather, it is constructed out of difficult polymers that can be machined right into more intricate patterns.

The Single Strategy To Use For Motorcycle Parts New Zealand Specialists

Bike suppliers news often cast these parts, but just for the manufacturing of bespoke components. Machining on five axes in today's globe is the ways by which any kind of layout form may be recognized.

Select Runsom for your tailored bike parts! We have the capacity to produce complicated and elegant parts making your bike matchless.

Right here are a couple of instances of metals usually made use of in motorcycle element machining. Light weight aluminum is the main product used by companies focusing on creating custom-made bike elements to develop the majority of these components. In the past, we would certainly build our engines out of cast iron. On the various other hand, aluminum is quickly ending up being the product of option, partly because of the fact that it is a lot more light-weight.

Zinc refers to another steel that is very light in weight and has excellent machining top qualities because of its high mechanical stamina. This material may be formed into virtually any kind of shape and keeps its measurements well. Also mission-critical parts that require a high level of accuracy might profit from their usage.

Some Ideas on Motorcycle Parts New Zealand Specialists You Should Know

An additional metal that sees hefty use in the manufacturing of CNC-customized elements is magnesium. It is amongst the lightest steels that are now accessible and has excellent machinability attributes and strength compatible with its reduced weight. One of the disadvantages of magnesium is that its dirt might easily catch fire.

Since of its exceptional machinability and weldability, stainless steel is an alloy that is especially fit for CNC procedures. In addition to this, they have excellent corrosion resistance and pop over to this site a high visual appeal. Their most typical usage in producing different motorbike parts is fasteners, such as screws and bolts. Their low vulnerability to oxidation and rust makes them excellent for this usage.

Motorcycle Parts New Zealand Specialists for Dummies

It appears that CNC transforming and milling are the fundamental processes. In enhancement, it requires maintaining bars of material, most visite site frequently plastic or steel, in position and after that twisting a cutting device to remove sections of the product as the material is turned.

These methods are equally vital and generate parts with high precision and consistent high quality. The processes aid enhance the overall quality of the machined motorbike elements.

Motorcycle Parts New Zealand Specialists Fundamentals Explained